WARNING!

Do not try to cut vinyl with a laser; the heat of the beam on the vinyl surface generates a very toxic gas, vinyl chloride, which is dangerous if inhaled. It is also harmful to the equipment, causing oxidation and deterioration. Absolutely do not attempt to laser-cut vinyl.

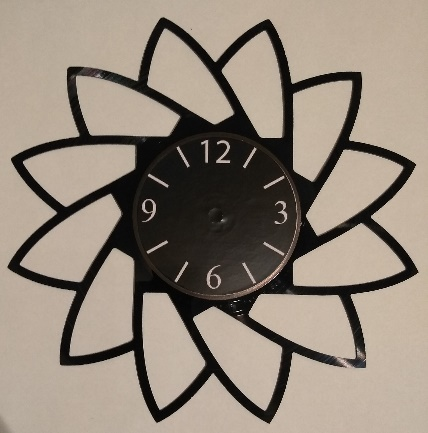

After working for over 20 years as an IT manager in a radio station, I retired in January 2013. I immediately wondered how to spend my available time. My passion has always been music, all kinds of music. After seeing a YouTube video of a Polish boy cutting old vinyl with a soldering iron, I was inspired to find a more rational and effective system to create watches from old records.

Initially born as a hobby, it then turned into a job. In recent years, I have attended many local markets, festivals, and village fairs, receiving positive feedback and continuously expanding my catalog of produced watches.

The first machine I used to make them was an aluminum 6040, no brand, self-built for the electrical and electronic parts. I still use it for heavier jobs. Over time, I realized I needed a smaller, more portable machine. Sometimes during markets, I receive requests for unique watches, and having a small machine on-site adds to the charm of seeing the work done in front of the buyer.

After various research, I chose a SainSmart 3018-Pro with the addition of the 3040 extensions. This versatile and relatively inexpensive machine in the small CNC field has a 30cm by 35cm worktop, making it ideal for my work. The ability to replace the spindle motor with a laser adds further opportunities since I also make wooden clocks.

Easy to assemble, with a GRBL compatible electronic board, it was a perfect choice considering I already had over 200 projects made using LaserGrbl.

Furthermore, to cut vinyl, you don't need a high cutting speed, and the supplied spindle is perfectly compatible with the cutters I already used.

After many tests, I arrived at a definitive choice; vinyl is not difficult to cut, but it is very challenging if the cutter vibrates or is not perfectly aligned. I normally use a 1.5mm two-straight cut cutter. I have tried helical cutters, but they leave the edges of the cut imperfect and require finishing manually with a file.

To make a clock from an old vinyl, I start by creating the project with Vectric Aspire. Here, I can convert images, DXF files, and PDF files into vector lines, which will then generate the G-code to be sent to the machine's controller board.

I use a basic scheme where I have already marked the diameter of the vinyl at 30cm, the space occupied by the 10cm disc label, and I place the various images and writings in the remaining spaces. Once the project is defined, including internal and external routes, I export the G-code ready to be used by Lasergrbl.

On the CNC, I have an MDF top with a hole in the center of the vinyl for fixing it, while the edges are secured with simple tape. This system guarantees excellent overall stability.

The speeds used are 1200mm/min for the advancement and 300mm/min for the descent of the cutter, with a rotation speed of around 1000 rpm.

Translate with Google Translator, Original in Italian.

AVVERTENZA!

Non tentate di tagliare vinili con il laser; il calore del raggio sulla superficie del vinile genera un gas molto tossico, il cloruro di vinile, pericoloso se inalato. È anche dannoso per le apparecchiature, causando ossidazione e deterioramento. Non tentate assolutamente di tagliare vinili con il laser.

Dopo aver lavorato per oltre 20 anni come responsabile informatico in una stazione radio, nel Gennaio del 2013 sono andato in pensione e subito mi sono chiesto come poter impegnare il tempo che avevo a disposizione. La mia passione era ed è la musica, ogni tipo di musica, e dopo aver visto un video su YouTube di un ragazzo polacco che tagliava vecchi vinili con un saldatore, è nata l’idea di trovare un sistema più razionale ed efficace per realizzare orologi da vecchi dischi.

![[Part 2] Advanced CNC Design with Vectric Aspire [Part 2] Advanced CNC Design with Vectric Aspire](http://www.sainsmartshop.com/cdn/shop/articles/Frame_36747_2_f374d9f8-a0e0-465e-80ed-1bb349fc0a3b.png?v=1737359282)

2 comments

Hi where can I get the 1.5mm straight cut cutter please

Bonjour, puis je savoir comment vous rendez une image svg compatibles avec la découpe cnc?